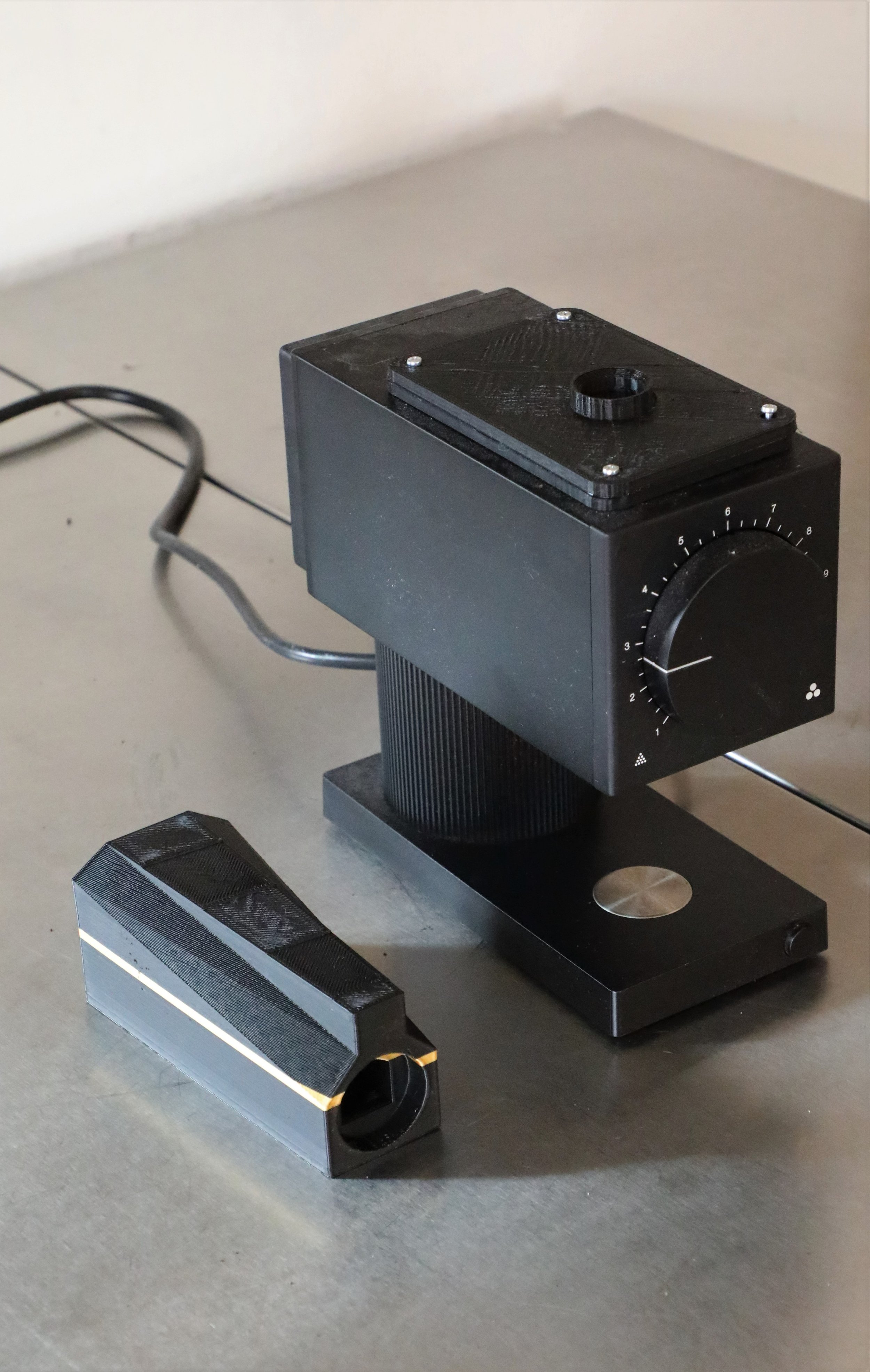

This actually works really well. Even though jams still happen, it’s less vexing because jams are so much easier to deal with. The chute is a detachable cup with some interfacing designed to match up to the base plate, and jams can be cleared by just a bit of shaking.

The cup has all the weird angles because of the really incremental design process. I started with a more rectangular tube with one face flat on the print surface, and then literally started cutting corners to save on print material. Then I designed in a support on the top face, because the tube was angled and would have probably fallen over otherwise. I like where the cup ended up, but I definitely didn’t start the design process with that in mind.